We are happy to help you with our future technology and professional team.

Raw materials arriving at our warehouse are brought to the quality control laboratory in accordance with the sampling procedure, and if the analysis results are appropriate, they are approved for entry into the company.

Raw materials are analyzed based on certain control criteria based on European Pharmacopoeia10.8 methods.

These controls are visual control, solubility control, density determination, moisture determination, pH determination, viscosity determination.

After approvals, weighing is carried out in accordance with GMP in a special weighing room equipped with HEPA filters and humidity controls.

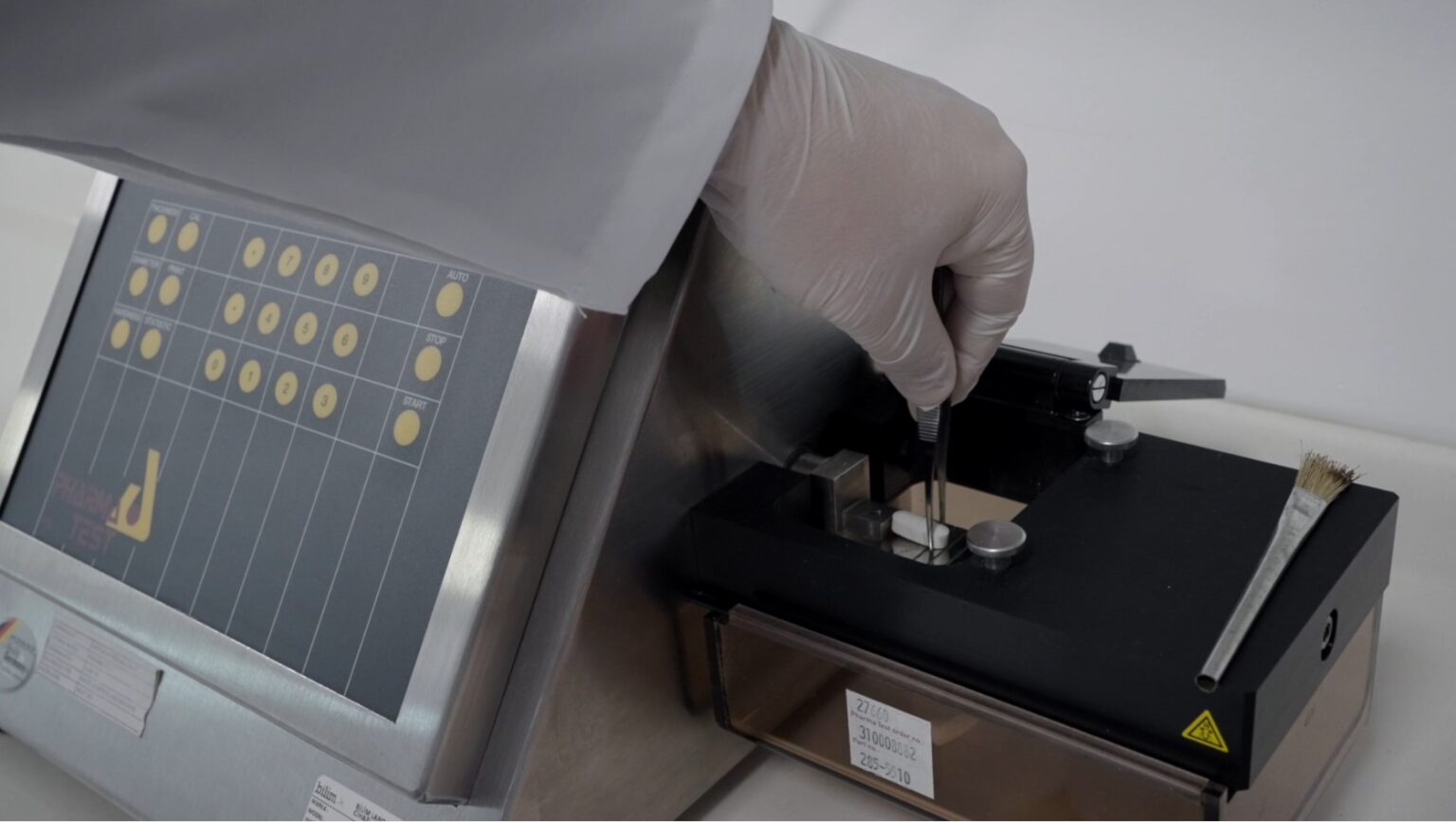

The controls performed on finished products are visual control, solubility control, organoleptic control, volumetric and quantity control, moisture determination, pH measurement, density determination, viscosity determination, hardness determination, diameter-thickness measurement, quantity determination (HPLC), gas chromatography.

At the same time, with our state-of-the-art X-RAY device, finished products are controlled within the scope of both quality control and food safety.

In this way, in case of a possible visual nonconformity or physical contamination, this situation is detected and prevented before the product is shipped. Thus, it is aimed to prevent customer dissatisfaction.

Intermediate process controls are also carried out during production and the operability of the process is kept under constant control.

The approval mechanism operates continuously in the processes from raw material acceptance to the final product stage, necessary corrective-preventive actions are initiated in case of any nonconformity, and continuous improvement studies are carried out for our processes.

The raw materials delivered to our warehouse are delivered to the microbiology laboratory with the sampling procedure. The delivered raw materials are analyzed in the microbiology laboratory based on the analysis certificates of the raw material and the methods of Ph. Eur.10.8 European pharmacopoeia, Total Aerobic Microbial Count (TAMC), Total Mold and Yeast Count (TMYC) and pathogens such as Escherichia coli and Salmonella, which are important for our health.

Before our products are filled, apart from routine controls, production is started after hygiene controls in the production area with a luminometer device. Then, microbiological analyzes of semi-finished and finished products are performed by Ph. Eur.10.8 is completed based on the methods of the European pharmacopoeia. In addition, our water analyzes are also analyzed by membrane filtration method. Compliance is monitored by microbiology experts.

Simply bring your brand, the specifications or the formula of the product you intend to produce to Pharmarosso.

Tell our experts about your product and exchange ideas.

Let our experts prepare R&D studies for you and present them to you.

Let your product be produced with fully automatic state-of-the-art machines in European standards.

Get your product ready for delivery with our packaging design and packaging services.

Getting an accurate diagnosis can be one of the most impactful experiences you can have.

Copyright © Pharma Rosso 2025 All Rights Reserved.